Process innovation

On average we invest around 85 million Euros a year.

These investments allow us to not only raise our productivity but to also improve our product quality, logistic processes and environmental achievements.

-

Mathematical models behind the blast furnaces

The steering and optimising of our blast furnace process is done via mathematical models.

-

Biological water purification

In our coking plant, polluted water is purified biologically. This installation is state of the art in Europe.

-

Efficient quay planning

Yearly, around 3,000 ships dock at our ArcelorMittal site in Ghent. This process runs smoothly thanks to our quay planning system

-

Automated converter

We have automated the casting processes in order to increase our factory’s productivity.

-

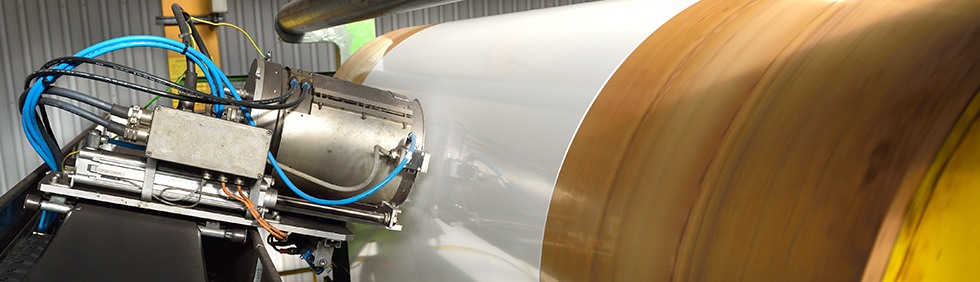

Measuring of the paint layers’ thickness

In the organic coating, the thickness of the paint layers is measured online. This enables us to fulfill our customers’ needs.

-

Revaluing CO and CO2

In light of the Carbon2Value project we separate CO and CO2, derving from our process gasses, in order to convert them into chemical building blocks and biofuel. This project is supported by the ‘Interreg 2 Seas’ programme.

-

Industry 4.0

Every day our co-workers go in search of the next step towards the ‘steel factory of the future’, constantly pushing the limits of steel making.