The production departments

ArcelorMittal Gent produces steel from A to Z: in the different production departments, we convert raw materials -mainly iron ore and coal- into high quality steel.

Hot phase (Ghent)

-

Handling of raw materials

The raw materials arrive by ship at ArcelorMittal Gent, where they are then carefully seperated.

-

Coking plant

Coal cannot be used directly in the steel making process. We first need to convert it into coke.

-

Sinter plant

Iron ore as well cannot be used directly into the steel making process. It is thus first converted into sinter.

-

Blast furnaces

The sinter and coke are loaded into the blast furnaces where they are melted into liquid hot metal.

-

Steel shop

In the steel shop, liquid hot metal is converted into steel, which we then solidify into steel slabs.

-

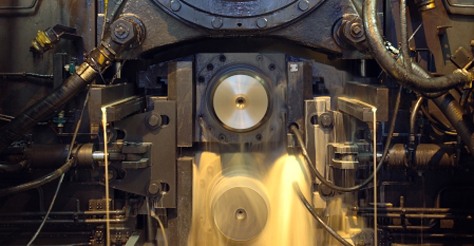

Hot strip mill

The slabs are rolled into steel strips with a thickness varying between 1.25 to 13mm

Cold phase (Ghent, Liège, Genk and Geel)

-

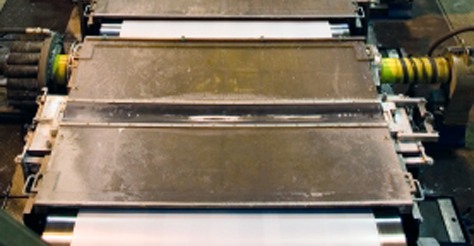

Cold rolling mill

The hot rolled strips are converted into cold rolled steel plates with an average thickness of around 0.15 to 3mm

-

Galvanising line

In our galvanising lines, we are able to add an additional protective zinc coating to our steel so that it becomes corrosion-resistant.

-

Jet Vapor Deposition

The JVD technology coats a moving strip of steel in a vacuum chamber, by vaporizing zinc onto the steel.

-

Electrolytic galvanising line

In our production line in Genk, we galvanise our steel via an electrolytic deposition process.

-

Organic coating line

We are able to, in both Ghent as well as Geel, add a layer of paint unto our steel plates.

-

Tailor-welded blanks

In Ghent, ready-made parts that can be used for the body work of cars are produced.